Dual-Acting Pneumatic Engine

Thermal-Fluid Sciences I & II, Junior Undergrad

Team members: Alexandra Gobeler, Lauren Markey

Skills: Solidworks, Thermal-fluids, Milling, Turning, Water jet, Laser cutter, Luck

As a staple of the Rowan mechanical engineering curriculum, the air engine was perhaps "THE" project that defined a generation of Rowan engineers.

All Videos

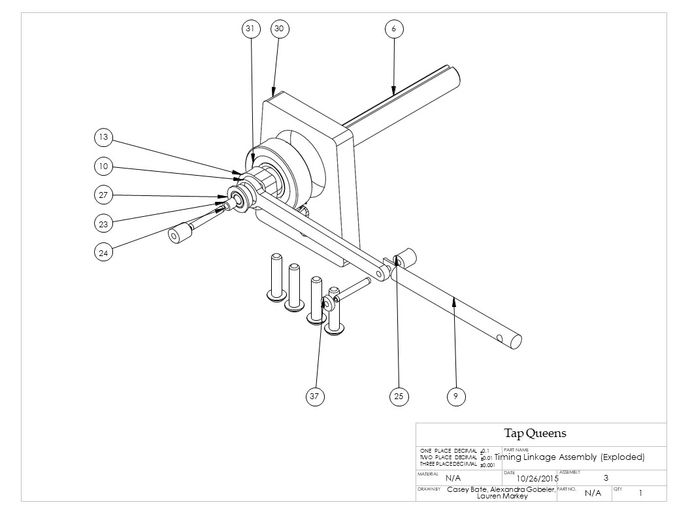

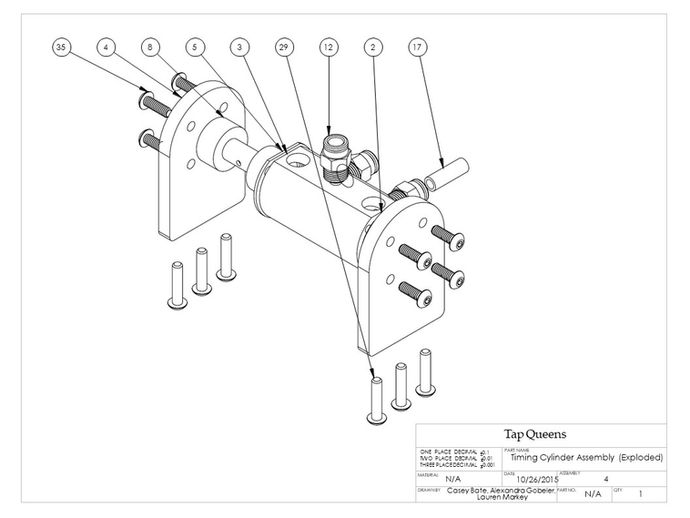

The goal of this project was to build the fastest 25cc dual acting air engine, virtually from scratch. Previous years were completely from scratch, however, in 2015 we were allowed to purchase a piston/cylinder online which greatly improved sealing and efficiency of previous student made models. The rest was completely designed and manufactured by the student team. The engine had to be dual-acting meaning that incoming air acted on the cylinder during both the up and the down stroke. All teams were limited to the roughly 100 PSI shop air, meaning efficiency was the key to success. We accomplished this through optimal valve timing, and minimizing the room the air had to expand before reaching the cylinder. Later alterations included expanding choked flow points on both the inflow and exhaust. We estimate these alterations added 200 rpm from when the above video was taken. Additionally, we were graded on weight so much of the engine was manufactured out of acrylic.

Result: School Record 3100 RPM

Our engine set a new school record of 3100 rpm. The previous record was 2600 set some time during the 10 year history of this project. Designs were completed in about a week, manufacturing took two weeks, and testing with part interchanging took an additional two weeks. The part design can be viewed below. File manipulation has caused some image issues so a downloadable version can be found here:

The Tap Queens

This hat was already out of style

Stripes and plaid??

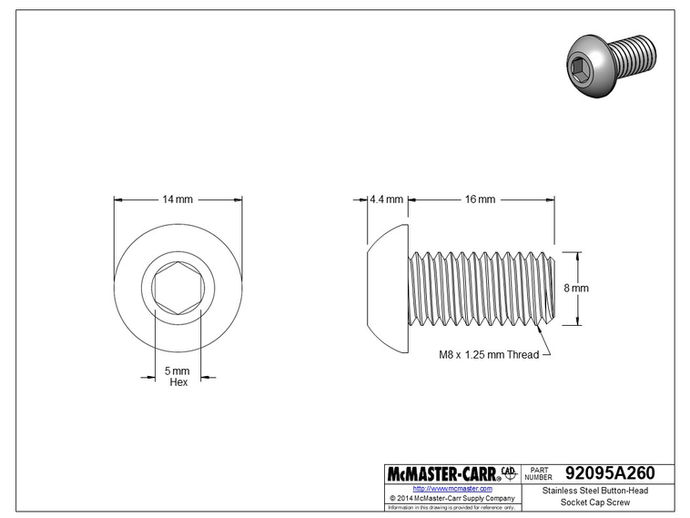

*We had all decided to take a tap dancing class this semester and "Trap Queen" was the song of the previous summer. We also drilled and tapped a lot of holes for this project.